Mixer

High efficiency of alternate arranged interior and exterior propeller blades. Short time and horsepower required for mixing. Rapid discharging with pneumatic valve. Unique cylinder operated sealing with no leakage. Can be mounted with fats, fish oil and sugar ejection system. Safe operation and durable body. Easily maintenance..

| MODEL | CAP. T/H | HORSEPOWER (HP) | OUTLINE (LxWxH) |

| SBM-300 | 120 | 3 | 1400 x 900 x 1500 |

| SBM-1500 | 650 | 7.5 | 2600 x 1300 x 1900 |

| SBM-3200 | 1300 | 10~15 | 3100 x 1300 x 2000 |

| SBM-5300 | 2200 | 20~25 | 3700 x 1500 x 2300 |

| SBM-6500 | 2700 | 25~30 | 3800 x 2300 x 2100 |

| SBM-9600 | 4000 | 50~60 | 4100 x 2500 x 2600 |

Hammer Mill

The design of an enlarged pulverizing chamber and a sieve screen which is large in area ensures a high efficiency for passing through of the material pulverized. Fully making use of the impact among particles enables a superb pulverizing effect and even fineness of materials pulverized. Multiple use for every kind of crushing materials.

| MODEL | CAP. T/H | HORSEPOWER (HP) | OUTLINE (LxWxH) |

| SHM-1 | 0.3 - 1.5 | 7 1/2 - 10 | 1000 x 800 x 500 |

| SHM-2 | 1.0 - 2.0 | 15 - 20 | 1300 x 900 x 800 |

| SHM-3 | 2.0 - 3.0 | 20 - 30 | 1300 x 1100 x 800 |

| SHM-4 | 3.0 - 5.0 | 50 - 75 | 1680 x 1380 x 1400 |

| SHM-5 | 6.0 - 8.0 | 100 - 125 | 1800 x 1100 x 1200 |

| SHM-6 | 8.0 - 10 | 125 - 150 | 2200 x 1300 x 1400 |

Fine Pulverizer

The materials can be ground to the fineness 60~100 mesh pass through 85~95%. Rotaied swing hammer crushing the material easily with large capacity. Special alloy material of hammer and teeth liner for long using life and anti-wear character. Adjustable hammer swing diameter to match different material and also prolong the spare parts life. Generally, The hammer life is about 2000-4000T. The liners life is about 4000-8000T, lt is depend on the material component. Unique screen under the hammer not only to inner grinding capacity but also prevent large and weightless fiber from passing through out and then to the Die bole. To match with efficient and sharp air separator ensure the biggest particle size under 40 mesh.

The pellet mill is the key equipment in feed production. It is characterized by high output, good performance and good quality, etc. It has rigid structure, main shaft SKF bearings and overload safety device with long life and no malfunction. It is a high value feed producing equipment.。

| MODEL | CAP. T/H (60 mesh pass 85%) |

HORSEPOWER (HP) | LOCATION AREA (m) |

| SAP-1SH | 0.15~0.3 | 5 ~7.5 | 1.2*0.9*1.2 |

| SAP-2DH | 0.3~0.5 | 15~20 | 1.5*1.3*1.3 |

| SAP-3TH | 0.5~1.0 | 30~40 | 1.8*1.7*1.5 |

| SAP-4TH | 1.0~1.5 | 60~75 | 1.9*1.8*1.7 |

| SAP-5FH | 1.5~2.5 | 125~150 | 2.9*2.5*2.3 |

| SAP-6SH | 2.5~4.0 | 175~200 | 2.9*2.7*2.3 |

| SAP-7SH | 5.0~7.0 | 225~250 | 3.2*3.0*2.3 |

| SAP-8EH | 6.0~9.0 | 275~300 | 3.3*3.0*2.5 |

Vertical Super Mill

Soon Strong Vertical Super Mill is suitable for Fish & Shrimp pellet process. The grinding size is to 60~100 mesh and the pass through rate is about 95%~99%. The special cutter and with Tungsten steel tee liner are in specification. It will be provided long using life. The cutter using life is about 1500~3000 tons depended on material. It is also adjusted the grinding size with inside separator and without stop running.

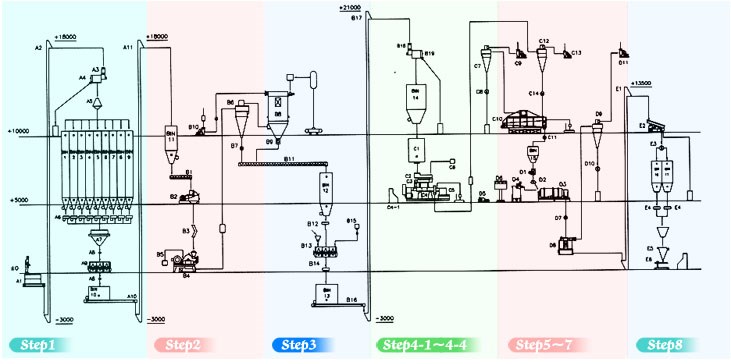

Animal.Aqua feeds plant process