Single Extruder

When material mass are extruded out from barrel to die plate, It should be cut to suitable length which about 2-3 times of diameter, There are 18branches on cutter seat. So, you can assembly the correct amount cutter as you want. It also driven by inverted motor to control rotated speed .It is easy to adjust the rotation of cutter seat on producing process to achieve the best pellet outline shape.

| MODEL | CAP. T/H (φ3.0MM) | HORSEPOWER(HP) | LOCATION AREA |

| SEP-25 | 0.2~0.4 | 25~30 | 3.6*1.5*1.6 (M) |

| SEP-100 | 0.8~1.5 | 60~75 | 4.0*1.8*1.6 (M) |

| SEP-150A | 1.5~2.5 | 100~125 | 4.0*1.5*1.8 (M) |

| SEP-200 | 3.0~4.5 | 150~175 | 4.5*1.5*1.8 (M) |

| SEP-250 | 5.0~6.0 | 200~250 | 5.5*2.5*1.8 (M) |

| SEP-300 | 6.0~8.0 | 250~300 | 5.5*2.7*2.9 (M) |

Binary Axis Extruder

The pellet die is the most important part of the pellet mill. The pellet die is made of high quality material. It has merits such as long life, high output, less cost and power, etc

| MODEL | CAP. T/H (φ3.0MM) | HORSEPOWER(HP) | LOCATION AREA |

| SEP-120 | 1.6~2.0 | 150~175 HP | 4.6*1.1*1.2 (M) |

| SEP-180 | 3.5~4.0 | 215~250 HP | 5.8*1.3*1.6 (M) |

| SEP-300 | 8.0~10.0 | 400~450 HP | 8.0*1.4*1.8 (M) |

Pellet Mill

*The above capacity is obtained with φ2.2mm die for prawn feed, the bracket indicates animal feeds production with φ 4.0mm die

| MODEL | CAP. T/H | HORSEPOWER |

| SPM-2 | 1.0 - 1.5 (2.0 - 3.0) | 75 |

| SPM-3 | 1.5 - 2.0 (3.0 - 5.0) | 100 |

| SPM-4 | 2.0 - 2.5 (6.0 - 9.0) | 150 |

| SPM-5 | 2.5 - 3.5 (10 - 13) | 200 |

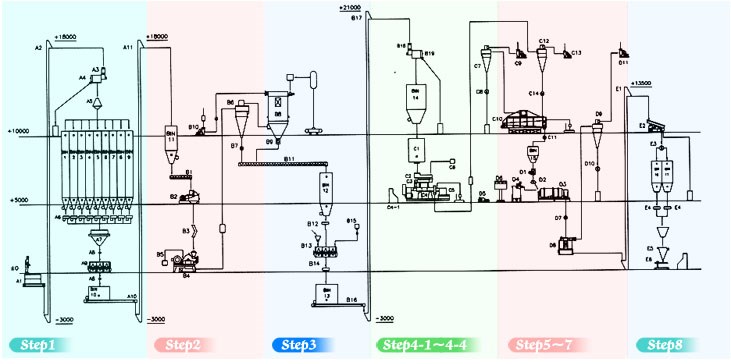

Animal.Aqua feeds plant process