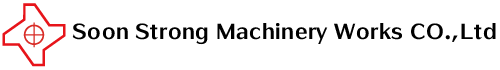

Vertical Roller Mill

Feed requirement & Products

* Inlet size : Under Dia.15mm

* Hardness : Under Mohs 6(special design for Above 6)

* Quartz Content : Under 5%

* Product size range : d97=10~50μm (1340~325 mesh)

* Moisture content : Under 5%

Material application

■ Calcium carbonate

Limestone Marble Calcite Dolomite

■ Ceramic Materials

Feldspar Quartz Kaolin clay

■ Industrial Minerals

Barite Bentonite Coal Cokes Graphite Gypsum Rock phosphate Slaked lime Talc Zeolite

| Model No. | Mill power | Classifier power | Classifier (Q`ty X Dia.) |

Capacity d97=10μ |

Capacity d97=20μ |

Dia.(WXH) |

| SVRM-750C3 | 100kw(130HP) | 11kw(15HP) | 3 X 315(mm) | 2 T/H | 4 T/H | |

| SVRM-1050C5 | 200kw(265HP) | 11kw(15HP) | 5 X 415(mm) | 4 T/H | 8 T/H | 4.2X6.1(m) |

| SVRM-1200C5 | 300kw(400HP) | 15kw(20HP) | 4 X 500(mm) | 6 T/H | 12 T/H | 4.6X7.1(m) |

| SVRM-1500C6 | 450kw(600HP) | 15kw(20HP) | 6 X 500(mm) | 9 T/H | 18 T/H | |

| The capacity as list shown is took standard on grinding limestone. The real capacity is depended on material specification & fineness of requirement. | ||||||

SVRM Feature

■ Under S.A=23000cm2/g products is no need 2nd classifying equipment to classify. It could be produced directly from SVRM

■ Grinding liners is made on high wear resistant with high chrome alloy for disk and rollers to provide high quality to customer.

■ Without changing wearing of rollers & disk in 5 years for grinding limestone on user experience record that would be an advantage on cost & fix

Ball Mill

Material requirement

* Inlet size: Dia.under 10mm

* Hardness: Under Morhs 7 for reference

* Product size range: d97=40~75μm (350~238 mesh)

■ Calcium carbonate

Limestone Marble Calcite Dolomite

■Ceramic Materials

Feldspar Quartz Kaolin clay

■Industrial Minerals

Barite Bentonite Coal Cokes Graphite Gypsum Rock phosphate Slaked lime Talc Zeolite

Soon Strong unique design

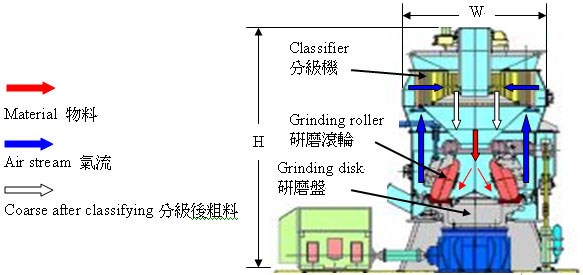

1. Special liner design for up the efficiency of ball mill and reduce weight to low down the power use. The liner material could be high Cr,、Mn or ceramic for satisfied customer needs (See Fig.1)

2. Design & manufacture the liner cannelure to fit the material property. Let the material be more efficiency in milling

3. Robust gear ring and main body to fit any situation use.

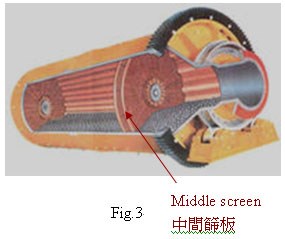

4. Middle screen (See Fig.3) design could avoid material jam and separate two chamber to keep material in best efficiency. Extend the coarse material mill time.

5. Belt or gear box transmission choice by ball mill size

6. Whole ball mill is in negative pressure design that prevent dust pollution

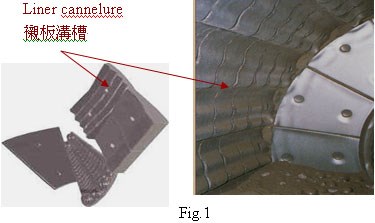

7. Inlet & outlet adapted inner screw design to keep away material jam (See Fig.2)

| Model (Dia.xL) |

Rotaryspeed (R.P.M.) |

High Cr stee ballweight (Ton) |

Weight of ball mill main-body (Ton) |

Grinding size of production (μm) |

Capacity (Ton/h) |

Power (HP) |

| SBM-0616 (O6`x16`) |

24 | 15 | 25 | 35~125 | 2.0~4.5 | 150~250 |

| SBM-0624D (O6`x24`) |

23 | 36 | 3.0~6.5 | 250~300 | ||

| SBM-0716 (O7`x16`) |

21 | 27 | 38 | 3.0~7.0 | 300~375 | |

| SBM-0724D (O7`x24`) |

40 | 55 | 5.0~10.0 | 325~400 | ||

| *產量依產品細度與現場實際狀況而定 | ||||||

Raymond Roller Mill & Mini Raymond Roller Mill

Material requirement件

* Inlet size: Dia.under 8mm

* Hardness: Under Morhs 5

* Product size range: d97=44~125μm (325~100 mesh)

■ Calcium carbonate

Limestone Marble Calcite Dolomite

■ Ceramic Materials

Feldspar

■ Industrial Minerals

Barite Bentonite Coal Cokes Graphite Gypsum Rock phosphate Slaked lime Talc Zeolite

| SRM series specification | ||||

| Model | Ring size | SRM power (HP) | Capacity (Ton/h) (2) | Whole plant power (1) |

| SRM-2435 | 24” | 15 | 0.5~1 | 60 |

| SRM-3036 | 30” | 20 | 1~1.3 | 84 |

| SRM-3637 | 36” | 30 | 1.3~2.2 | 105 |

| SRM-4247 | 42” | 40 | 2~4 | 150 |

| SRM-5057 | 50” | 75 | 3.5~7 | 250 |

| SRM-6068 | 60” | 150 | 6~11 | 350 |

| (1)Whole plant equipment included Crusher、Elevator、Breaker、Fan、Classifier, storage & dust collection equipment of raw material (2)The capacity is adjustable by product particle size & the material status. The above data is for reference. |

||||

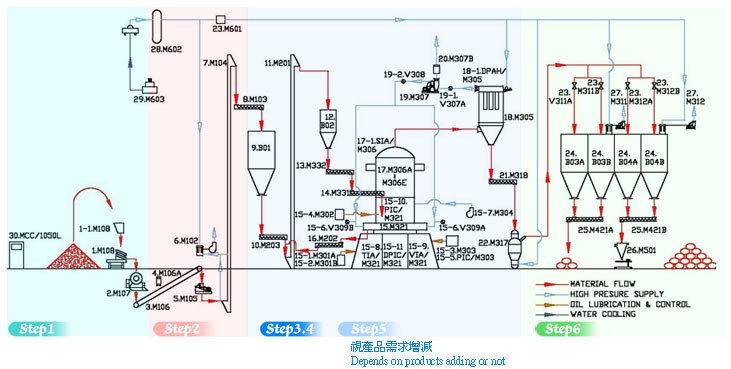

Mineral.Chemical Grinding whole plant eqipments process