Separator series

|

|

Fig.1 Fig.2 Fig.3 |

➤ How to choose a separator

| Classifier | Classifing | Cap. | Application |

| Whizzer separator(Fig.3) | 20~150μm0~97% pass through |

1.0~10 ton/hr |

Foods, Mineral, Chemicals, Forage, Cosmestic, Pigment, |

| Single Micron separator(Fig.1) | 4.5~150μm 97~99.9% pass through |

1~8 ton/hr |

|

| Multi-Micron separator(Fig.2) | 1~150μm 97~99.9999% pass throug |

1~18 ton/hr |

|

| Above data is reference. The data should accord by particle size and in real situation. The input should be 70% under 20μm | |||

➤ Soon Strong Separator series

| Single Micron separato (Caco3 Base) | ||||

| Mode | Outside dia.(mm) | Air Flow(m3/h) | Fine Yields (Kg/h) (Kg/h) for ref |

Motor Rating (kw) |

| 300meshx98% (P.R) | ||||

| SMS-1 | 600 | 900 | 150 | 0.75 (1HP) |

| SMS-3 | 900 | 4800 | 750 | 2.2 (3HP) |

| SMS-4 | 1250 | 9000 | 1500 | 5.5 (7.5HP) |

| SMS-5 | 2100 | 18000 | 3000 | 7.5~15 (10~20HP) |

| SMS-6 | 2600 | 36000 | 6000 | 30 (40HP) |

| ✦ Advantage 1. High classifying capacity 2. The classifying range is very wide (4.5~150μm) 3. Adjust particle size without shouting down 4. Apply in single unit or integrated system 5. Special seal design for against the powder leakage |

||||

| Multi-Micron separator (Caco3 Base) | ||||||

| Model | Wheel Q`ty x dia (mm) |

Cut Size d97 (μm) |

Air Flow (m3/h) |

Fine Yields (Kg/h) | Motor Rating (kw) |

|

| d97=10μm | D97=20μm | |||||

| SUAC-100-3 | 3x100 | 4~60 | 750 | 135 | 210 | 3x3.7 (5HP) |

| SUAC-200-8 | 8x200 | 5~75 | 8000 | 1440 | 2240 | 8x5.5 (7.5HP) |

| SUAC-315-3 | 3x315 | 6~90 | 7500 | 1350 | 2100 | 3x11 (15HP) |

| SUAC-315-6 | 6x315 | 9~140 | 15000 | 2700 | 4200 | 6x11 (15HP) |

| SUAC-630-3 | 3x630 | 9~150 | 30000 | 5400 | 8400 | 3x22 (30HP) |

| ✦ Advantage 1. High capacity and particle size distribution is moreconcentractive compared with single micron classifier 2. Low abrasion rate. Apply to hard or non-pollution powder product classifying 3. Low energy to consumption 4. Above data is for reference & the inlet material need Require 70% under 20μm |

||||||

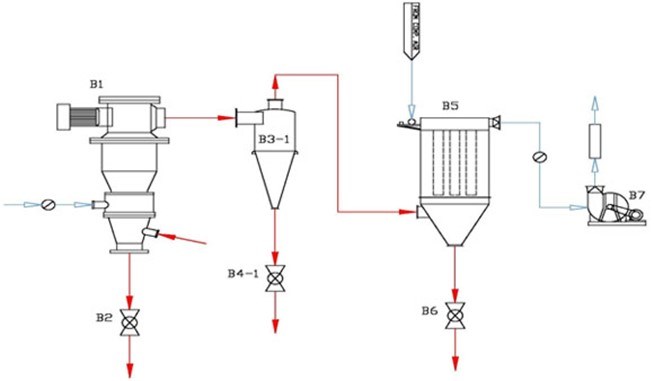

B1. Multi-Micron Separator

B2. Rotary Valve

B3-1. Cyclone Collector

B4-1 Rotary Valve

B5. Pullsaire Collector

B6. Rotary Valve

B7. Exhaust Fan

◉ Simple & high efficiency process flow for classifying

◉ Coarse powder after classified collected at cyclone than fine powder collected at bag filter. The advantage is extended bag filter life & more efficiency in powder collecting

◉ Low production cost & more durable design

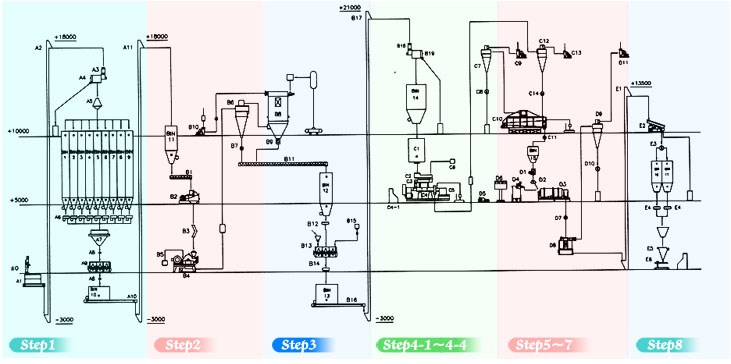

Animal.Aqua feeds plant process

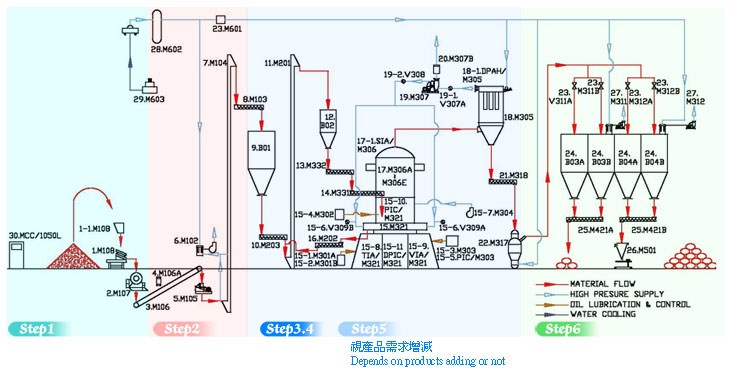

Mineral.Chemical Grinding whole plant eqipments process